News

- The company provides special price oilfield drilling and production solid control system equipmentThe function of JB/W15 series agitator is to maintain the uniformity of the drilling fluid and suspend the solid phase particles, and to continuously and reliably stir the drilling fluid. The oil drilling fluid JB/W series mud mixer produced by the company is below 5.5kW. The cycloidal reducer is adopted, and the JB/W series mud mixer is suitable for the stirring action of petroleum drilling fluid. It has the advantages of compact structure, small floor space and good mixing effect; 7.5kW drilling fluid mud mixer adopts worm and worm type The reduction drive has the advantages of large transmission torque, stable operation and reliable operation. Mud Agitator with double impeller JB/W15 Frequency: 50 Hz Voltage: 380 V Power: 15KW IP: 55 Explosion Proof: Yes RPM: 1480 Mud Agitator with double impeller JB/W15 Frequency: 60 Hz Voltage: 460 V Power: 15KW IP: 55 Explosion Proof: Yes RPM: 1775

2023 07/31

- All kinds of hardware tools and petroleum machineryYAOU TOOLS MANUFACTURING INC is a large-scale group, which specializes in designing, manufacturing, processing, selling YAOU Brand series Tools, such as Hand Tools, Tool Sets, Tools for Houses and Cars, The products are widely used in Home & Garden, Machine Manufacturing, Construction Decoration, Auto Maintenance and so on, the products have enjoyed very high market share and received good reputation in Europe, USA, Middle East and Southeast Asia countries and have many agents at home and abroad--- The factory of YAOU TOOLS MANUFACTURING INC in China Mainland mainly produces Patent Hammers (Patent No.:200720148347.6), Pipe Wrenches (Patent No.:200720155895.1), Axes (Patent No.:200830004408.1) We also accept OEM and customers' drawings and samples. YAOU Spirit: The quality bases on Profession, The value comes from Creation. YAOU Philosophy: Profession, Simpleness, High Effection, Insistence. YAOU Aim: Create the highest value for customers. YAOU Tenet: Customers feel comfortable, Merchants feel relieved. Sincerely Invite AGENTS from home and abroad on mutual benefits!

2023 04/13

- Warmly celebrating the official launching of YAOU Co., Ltd `s website!YAOU GROUP TOOLS MANUFACTURING INC is a large-scale group, which specializes in designing, manufacturing, processing, selling YAOU Brand series Tools, such as Hand Tools, Tool Sets, Tools for Houses and Cars, The products are widely used in Home & Garden, Machine Manufacturing, Construction Decoration, Auto Maintenance and so on, the products have enjoyed very high market share and received good reputation in Europe, USA, Middle East and Southeast Asia countries and have many agents at home and abroad--- The factory of YAOU TOOLS MANUFACTURING INC in China Mainland mainly produces Patent Hammers (Patent No.:200720148347.6), Pipe Wrenches (Patent No.:200720155895.1), Axes (Patent No.:200830004408.1) We also accept OEM and customers' drawings and samples. YAOU Spirit: The quality bases on Profession, The value comes from Creation. YAOU Philosophy: Profession, Simpleness, High Effection, Insistence. YAOU Aim: Create the highest value for customers. YAOU Tenet: Customers feel comfortable, Merchants feel relieved. Sincerely Invite AGENTS from home and abroad on mutual benefits!

2023 03/21

- Warmly celebrating the official launching of YAOU Co., Ltd `s website!YAOU GROUP TOOLS MANUFACTURING INC is a large-scale group, which specializes in designing, manufacturing, processing, selling YAOU Brand series Tools, such as Hand Tools, Tool Sets, Tools for Houses and Cars, The products are widely used in Home & Garden, Machine Manufacturing, Construction Decoration, Auto Maintenance and so on, the products have enjoyed very high market share and received good reputation in Europe, USA, Middle East and Southeast Asia countries and have many agents at home and abroad--- The factory of YAOU TOOLS MANUFACTURING INC in China Mainland mainly produces Patent Hammers (Patent No.:200720148347.6), Pipe Wrenches (Patent No.:200720155895.1), Axes (Patent No.:200830004408.1) We also accept OEM and customers' drawings and samples. YAOU Spirit: The quality bases on Profession, The value comes from Creation. YAOU Philosophy: Profession, Simpleness, High Effection, Insistence. YAOU Aim: Create the highest value for customers. YAOU Tenet: Customers feel comfortable, Merchants feel relieved. Sincerely Invite AGENTS from home and abroad on mutual benefits!

2023 02/10

- RUGAO YAOU TOOLSYAOU TOOLS MANUFACTURING INC is a large-scale group, which specializes in designing, manufacturing, processing, selling YAOU Brand series Tools, such as Hand Tools, Tool Sets, Tools for Houses and Cars, The products are widely used in Home & Garden, Machine Manufacturing, Construction Decoration, Auto Maintenance and so on, the products have enjoyed very high market share and received good reputation in Europe, USA, Middle East and Southeast Asia countries and have many agents at home and abroad--- The factory of YAOU TOOLS MANUFACTURING INC in China Mainland mainly produces Patent Hammers (Patent No.:200720148347.6), Pipe Wrenches (Patent No.:200720155895.1), Axes (Patent No.:200830004408.1) We also accept OEM and customers' drawings and samples. YAOU Spirit: The quality bases on Profession, The value comes from Creation. YAOU Philosophy: Profession, Simpleness, High Effection, Insistence. YAOU Aim: Create the highest value for customers. YAOU Tenet: Customers feel comfortable, Merchants feel relieved. Sincerely Invite AGENTS from home and abroad on mutual benefits!

2023 01/05

- YAOU Special Tools Registered TrademarkWarmly celebrate the successful registration of the special tool trademark of Rugao YAOU Company.

2022 12/14

- mining machinery, processing machinery, various hardware tools, small household appliancesHello there! Our company is a large-scale comprehensive foreign trade company established in 2004. The company has strong financial strength, high technical and foreign trade talents. The company mainly deals in petroleum machinery, mining machinery, processing machinery, various hardware tools, small household appliances, etc. If you are interested, please contact us. We will sincerely relieve you of all purchasing troubles with first-class service, best quality and best price. All products of cooperative factories have passed various product quality certifications. Our website: Https://ntyaou.en.albaba.com. Email: sales@yaoutrade.com Best Regards. Mr. Xue (Sales Manager) -- RUGAO YAOU IMPORT & EXPORT TRADE CO.,LTD.

2022 12/03

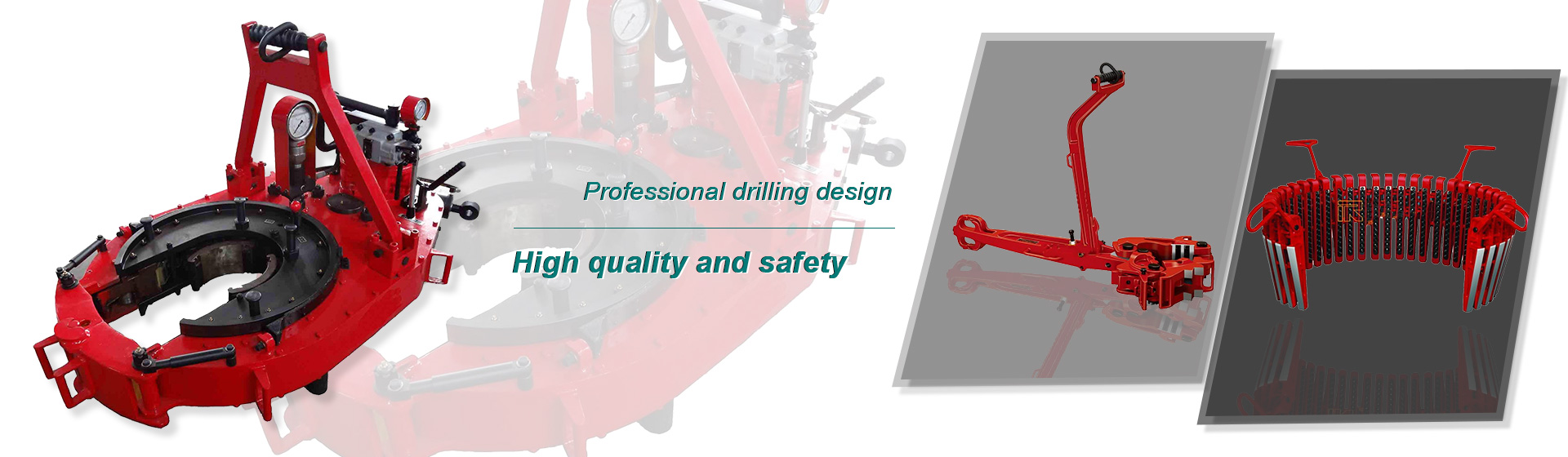

- oil drilling equipment, drilling special tools, various processing machinery, hardware tools, etc.The company has more than 20 years of trade service team, mainly engaged in oil drilling equipment, drilling special tools, various processing machinery, hardware tools, etc. At the same time, it provides some special products, so stay tuned. Main products: 1. Drill Pipe, Heavy Drill Pipe, Square & Hexagonal Kelly 2. Drill Collar & Non-magnetic Drill Collar 3. Stabilizers, Reamer, Hole Opener, Casing Scraper, etc 4. Kelly Valve, Safety valve, Check valve, and float valve 5. Hydraulic or Mechanical Drilling Jar, and Absorber 6. Fishing tools (Bowen serials), including overshot, spear, etc 7. Junk Mill, Casing Cutter, Safety Joint, etc 8. Hydraulic Bucking unit, Screw up and breakout Unit, Down hole motor tester, Jar tester, etc. 9 .Down hole motor 10. Processing machinery: shears, bending machines, hydraulic presses, bending machines, etc. 11. Various coal mine winches, oil field winches, ship winches, etc. 12. Various hand tools and electric tools. Keep in contact and any need; please feel free to contact me.

2022 11/21

- Sales of special tools for oil drillingThe company has more than 20 years of trade service team, mainly engaged in oil drilling equipment, drilling special tools, various processing machinery, hardware tools, etc. At the same time, it provides some special products, so stay tuned. Main products: 1. Drill Pipe, Heavy Drill Pipe, Square & Hexagonal Kelly 2. Drill Collar & Non-magnetic Drill Collar 3. Stabilizers, Reamer, Hole Opener, Casing Scraper, etc 4. Kelly Valve, Safety valve, Check valve, and float valve 5. Hydraulic or Mechanical Drilling Jar, and Absorber 6. Fishing tools (Bowen serials), including overshot, spear, etc 7. Junk Mill, Casing Cutter, Safety Joint, etc 8. Hydraulic Bucking unit, Screw up and breakout Unit, Down hole motor tester, Jar tester, etc. 9 .Down hole motor 10. Processing machinery: shears, bending machines, hydraulic presses, bending machines, etc. 11. Various coal mine winches, oil field winches, ship winches, etc. 12. Various hand tools and electric tools. Keep in contact and any need; please feel free to contact me. Web:https://www.ntyaou.com/ ;Http://www.yaoutrade.com Email: sales@yaoutrade.com;xueaihong@163.com

2022 11/10

- All kinds of hardware tools and petroleum machineryYAOU GROUP TOOLS MANUFACTURING INC is a large-scale group, which specializes in designing, manufacturing, processing, selling YAOU Brand series Tools, such as Hand Tools, Tool Sets, Tools for Houses and Cars, The products are widely used in Home & Garden, Machine Manufacturing, Construction Decoration, Auto Maintenance and so on, the products have enjoyed very high market share and received good reputation in Europe, USA, Middle East and Southeast Asia countries and have many agents at home and abroad--- The factory of YAOU TOOLS MANUFACTURING INC in China Mainland mainly produces Patent Hammers (Patent No.:200720148347.6), Pipe Wrenches (Patent No.:200720155895.1), Axes (Patent No.:200830004408.1) We also accept OEM and customers' drawings and samples. YAOU Spirit: The quality bases on Profession, The value comes from Creation. YAOU Philosophy: Profession, Simpleness, High Effection, Insistence. YAOU Aim: Create the highest value for customers. YAOU Tenet: Customers feel comfortable, Merchants feel relieved. Sincerely Invite AGENTS from home and abroad on mutual benefits! Previous: Warmly celebrating the official launching of YAOU Co., Ltd `s website!Next: Picture of percussion wrench and the difference between percussion wrench and electric wrench

2022 10/31

- National patent for fast-filling wellhead device without drilling machine cementingRecently, Dagang Oilfield Group Co., Ltd. independently developed the "Fast-free wellhead installation for drilling rigs" project, which won the national utility-type patent, marking the new cementing technology service of Dagang Oilfield Group Company to a new level. For a long time, the cementing industry has generally adopted the method of cementing the cementing tools on the joint surface of the joint section. With the continuous development of drilling technology in Dagang Oilfield, the use of batch drilling to speed up petroleum engineering is imminent. In order to shorten the cementing cycle and reduce the cementing construction intensity, Dagang Oilfield Group Cementing Technology Service Co., Ltd. has started the project [Research on Integrated Technology of Ending Island without Drilling Cementing" since the end of 2006. After nearly one year of research and implementation, the project has been successfully tackled, and its supporting project [Fast Wellhead Device for No-Drilling Cementing" has obtained national practical technical patents. "Fast-filled wellhead device for drilling-free cementing" successfully solved the need of manual tightening and raising short joints and cementing cement heads during cementing construction. It has high labor intensity, difficult to buckle, extremely easy to damage the thread buckle, and the degree of tightening is also It is difficult to control, the pressure bearing capacity of the thread can not be guaranteed, and the construction safety hazard is large, which provides technical support for ensuring the safety of cementing construction and shortening the drilling cycle. From the beginning of 2007 to the present, "Tiandao No-drilling Cementing Comprehensive Supporting Technology Research" has been successfully implemented in the Bohai No. 1 artificial island, and a total of 19 wells have been cemented, which has proved the advanced and effective technical solutions. feasibility.

2022 10/25

- Picture of percussion wrench and the difference between percussion wrench and electric wrenchPercussion wrenches are a very important type of manual wrenches in life and industry. Generally, the hand-held end of the percussion wrench is the percussion end and the front end is the working end to turn a nut or bolt of a certain size. Percussion wrenches are mostly used for assembly and disassembly of large hexagonal screws or nuts, which can be used by outside electricians to load and unload steel frame structures such as iron towers. Let's take a look at this tool intuitively through some pictures of tapping wrenches! Percussion wrench pictures The difference between percussion wrench and electric wrench The explosion-proof tapping wrench drill chuck involves a drill body, a jacket, a gear ring, a clamping jaw, a wrench and an anti-knock pad. The drill body has a cylindrical shape as a whole. The front and rear ends of the drill body are provided with outer circles of the same diameter. The center of the drill body is provided with a taper hole for docking with an electric drill rod or a main shaft. The outer surface of the drill body is provided with a jacket, and the drill body is provided with a clamping jaw for clamping and a ring gear for controlling the clamping jaw. The drill body is provided with a positioning pin hole for inserting a wrench. The positioning pin hole is used for inserting a wrench to adjust the advance and retreat of the clamping jaws. The wrench is provided with a rubber sleeve and a hanging hole. A circumferential groove is provided on the table surface at the front end of the drill body, and an anti-knock pad is provided in the groove and on the entire table surface. The new type of impact wrench adds an anti-knock pad on the front face of the drill body, which can ensure not only that it is not afraid of knocking, even if it is knocked without a wrench, it will not affect the service life and accuracy. The matched wrench is covered with a rubber sleeve, which is beautiful and easy to use. The utility model has simple overall structure and high clamping precision. An electric wrench is a wrench powered by a power source or a battery. It is a tool for tightening high-strength bolts, also known as a high-strength bolt gun. Mainly divided into impact wrenches, torsion shear wrenches, fixed torque wrenches, corner wrenches, angle wrenches. It is easy to operate, saves time and effort, and has a high price. The electric impact wrench is mainly for initial tightening of the bolt. Its use is very simple, that is, to align the bolt and pull the power switch. The electric torsion shear wrench is mainly used to finally tighten the torsion shear type high strength bolt. Its use is to align the bolt and pull the power switch until the torx head of the torsion shear type high strength bolt is interrupted. The electric fixed torque wrench can be used for initial tightening and final tightening. Its use is to adjust the torque first and then tighten the bolts. The electric corner wrench is also a kind of fixed torque wrench. Its use is to adjust the degree of rotation first, and then tighten the bolt. The electric angle wrench is a kind of electric wrench specially used to fasten the bolts at the angle of the steel frame. Its use is the same as the principle of the electric torsion shear wrench. The above content is to introduce to friends the knowledge about the pictures of knock wrenches and the difference between explosion-proof knock wrenches and electric wrenches. Percussion wrenches use the principle of leverage to turn bolts, screws, nuts, and other hand tools that hold the openings or sleeve fasteners of bolts or nuts with threads. It is very convenient to disassemble and assemble the hexagon nuts or bolts in a slightly concave place.

2022 10/17

- What are the specifications of the electric hammer bit? What are the characteristics of the electric hammer drill?The hammer drill is a hand-held power tool that combines the functions of "impact drill" and "electric hammer". The main impact drill is rotary cutting. Reciprocating hammering movement perpendicular to the rotating face of the drill bit. The electric hammer uses the movement of the piston to compress the gas to impact the drill bit. Without much effort, you can open holes in hard materials such as concrete, brick, and stone. So what are the specifications of the electric hammer bit? Electric hammer drill specifications There are many specifications and models of electric hammer drills. The drills we use when drilling different things are also different. The specifications of different material drills are also different. If you are worried about buying the wrong one, you must carefully understand the electric hammer. Drill specifications, only in this way can we find the drill we need. Electric hammer bit specifications are generally 6mm, 8mmx110mm; 8mmx160mm; 8mm, 10mm, 12mmx210mm, 10mm, 12mm, 16mm, 20mmx450mm. The main body of the cemented carbide hammer drill is made of high-quality alloy steel, and the cutter head is welded with cemented carbide. Used with various electric hammer machines, suitable for drilling holes in hard construction materials such as concrete and brick. It is a versatile and efficient punching tool in the construction and installation industries. The specifications of the electric hammer bit set are 5 * 110mm, 6 * 110mm, 6 * 160mm, 8 * 160mm, 10 * 160mm. Hammer drill features 1. A good shock absorption system can make the operator comfortable to hold and relieve fatigue. The way to achieve: through the "vibration control system"; through the soft rubber handle to increase the grip comfort. 2. Accurate speed control switch, the lower speed when you touch the switch, can help the machine to start drilling smoothly (for example, drilling on a smooth surface such as ceramic tiles, not only can prevent the drill bit from slipping, but also prevent the drill hole from breaking. Normal work High speed can be used to ensure work efficiency. 3. A stable and reliable safety clutch, also known as a torque limiting clutch, avoids the transmission of large torque reaction force generated by the bit jamming during use to the user, which is a safety protection for the user. This feature also prevents the gear unit and motor from stopping. 4. A comprehensive motor protection device, during the use, it is inevitable that granular hard objects will enter the machine (especially drilling the machine upwards, such as drilling the top of the wall), if the motor does not have certain protection, rotate at high speed It is easy to break or scratch the enameled wire by hard objects, which eventually leads to the failure of the motor. 5. The positive and negative reversal function can make the electric hammer drill more widely used. Its implementation is mainly achieved by switching or adjusting the position of the carbon brush. Usually, big-name tools will use the adjustment of the position of the carbon brush (rotating brush holder). The advantage of this is easy operation, effective suppression of sparks to protect the commutator, and extend the life of the motor. 6. The double function of the hammer drill has both the impact force of the electric hammer and the penetrating power of the electric drill. The above is the relevant introduction about the specifications of the electric hammer drill bit and the characteristics of the electric hammer drill. The electric hammer is actually a very common type of electric drill in our daily life, but the electric hammer uses the piston movement to make holes in the wall. Learn more about the relevant knowledge content in this area will make everyone more effective in actual operation.

2022 10/14

- Auto repair wrench set and auto parts market are closely linkedIn the course of maintenance, some illegal components are used to impersonate high-quality components; some replace original high-quality components with inferior ones; some disassemble the components of A-cars onto the same type of E-car and receive parts updates from customers respectively. Expenses; Some of them posed as defective parts and demolished old parts as quality products, which severely damaged the auto repair market's image and social reputation. If a garage repaired a car for a company in January this year, it promised to replace it with a new one, and actually replaced the body after the accident. Each technical supervision and quality inspection station or station, when quality supervision or quality follow-up inspection, finds that any violation of the above provisions shall be immediately stopped and reported at the same time. The quality of the maintenance team is low. The professional and technical requirements of the vehicle maintenance are high, and it has a great dependence on inspection and maintenance equipment. One-time investment in the opening more features. In some developed countries in the world, once quality problems occur after auto repair or the use of inferior parts causes an injury accident, maintenance companies will fall into a high compensation lawsuit and find it difficult to get out. In China, due to the national pilot market for professional markets, the construction of the legal system has yet to be improved. Some social organizations or even individuals who do not have sufficient conditions and capabilities are indiscriminate in recruiting and repairing personnel. Because of the low quality of personnel, the basic guarantee for maintenance quality is seriously lacking. If the distributors continue to sell unqualified products that have failed spot checks and have not undergone rectification (report inspection) qualification, they will be investigated and re-inspected. The low quality of auto parts With the socio-economic development, the auto parts market has become an important emerging industry. According to incomplete statistics, the city's auto parts stores have about 40 stores and are still growing. At the same time, the contradiction between the product quality of the auto parts market and its numerous problems has become increasingly prominent. It is worth noting that the automobile maintenance and auto parts markets are closely linked.

2022 10/08

- The difference between electric drill, impact drill, hammer drill and electric hammerThe electric drill is only relying solely on the motor to drive the transmission gear to increase the strength of the drill bit rotation, so that the drill bit can be scraped in the metal, wood and other materials. When the impact drill works, there are adjustment knobs at the drill chuck, adjustable drilling and impact drilling. However, the impact drill uses the gears on the inner shaft to perform the impact effect. The impact force is far less than that of the electric hammer. It can also drill reinforced concrete, but the effect is not good. Hammer drill (electric hammer) is not the same, it is the use of the bottom motor to drive two sets of gear structure, one set to achieve it drill, and the other set is to drive the piston, just like the engine hydraulic stroke, producing a strong impact force, accompanied by drilling effect. Power can split stone gold. The electric hammer is to allow the motor to drive the swinging gong to perform the bouncing movement so that the hoe has the effect of producing a gouge. The hydraulic pump uses the gas pressure transmitted by the air compressor to drive the pump hammer in the electric kettle to move back and forth, thereby producing a hammering effect on the ground. However, the electric hammer only chiseles and its hammer does not rotate. In short, the drill can only be drilled, and the impact drill can also have a slight hammering effect. A hammer drill can drill and a higher hammer, while an electric hammer can only hammer and cannot drill.

2022 10/04

- Why the rig drill pipe moves down?After the current rotary drilling rig is used for a period of time, when the drill rod is raised or lowered to return the operating handle to the neutral position, the drill rod is not immediately stopped, and it always descends by several tens of centimeters before it stops its movement. As the drilling rod of the rotary drilling rig is slipped down, this article discusses the common reasons for slipping down the drill pipe of the rotary drilling rig and the conventional judgment: 1, the cause of the failure The drill rod is fixed on the main hoist drum by a wire rope, and the drill rod can be raised or lowered accordingly when the drum is reeled or the wire rope is put. The power of the reels comes from the main winch motor that has been decelerated many times, and its stopping is achieved by a brake directly mounted on the reducer. During the process of raising or lowering the drill pipe, if the operating handle is returned to the neutral position and the drill rod can not be stopped quickly, there are three reasons for this: First, the brake lag; Second, the two hydraulic locks at the end of the motor end Failure, the motor cannot immediately stop the rotation under the effect of the wire rope torque; the third reason is easily overlooked. All drilling rigs have a drill rod release function. This function is provided by the solenoid valve 3 to release the brake signal oil, and then The solenoid valve 2 is connected to the inlet and outlet ports of the main winding motor through two oil pipes so as to ensure that the drill bit can always contact with the working surface and have a certain pressure during the drilling process. In other conditions, the solenoid valve 2 disconnects the two tubings from the inlet and outlet ports of the motor. If the disconnection is not timely, the above-mentioned failure phenomenon will occur. 2, determine the method (1) Judging solenoid valve 2 Determine whether the solenoid valve 2 is closed tightly: Remove the two oil pipes leading to the solenoid valve 2 at the motor, and plug the two oil ports on the motor end with two plugs. Then, operate the main winch mechanism. If it works normally, it means the fault. The solenoid valve 2 does not close tightly; if it is still abnormal, its components must be inspected. (2) Judging the hydraulic lock Determine whether there is a problem with the hydraulic lock: first adjust its two cylinders, if it does not work, then remove the lock and conduct a careful inspection. If no reason can be found, a ready-to-use lock can be used as an installation test to find out the cause of the fault. Since the hydraulic lock of the secondary winch is the same as that of the main winch, the lock of the secondary winch can also be borrowed and replaced one by one.

2022 10/02

- Solar rain, solar energy, solar rain, solar hot waterAs a new type of energy, solar energy is becoming more and more popular in daily life, and many companies have further researched and utilized it. There are a lot of solar energy in the market. I don't know if you know about solar rain and solar energy. What do you think of solar rain and solar energy? Is the price of solar rain solar water heater reasonable? How about solar rain and solar energy? Sun Rain, China's environmental protection business partner, one of the world's largest suppliers of solar water heaters and hot water systems. As a high-tech enterprise specializing in technology research, consumer manufacturing and market promotion of new energy applications such as solar energy, Sun Rain has provided solar water heating system treatment plans for millions of households around the world. The company's operating range touches: all-glass vacuum collectors and flat-panel solar water heaters, solar heating. Thermal wall China strong Solar rain series solar energy adopts the first heat exchange technology, instantaneous heating, no waiting, and has dealt with the problem that solar water heaters can not be used immediately after water supply. The water volume is sufficient, no longer limited by the capacity of the water tank, no matter bathing, washing, washing vegetables. All kinds of needs can be met one by one. Water tank heat preservation hot water is more durable Using the latest ceramic nano R-A thermal insulation film patent technology, the heat retention efficiency is improved by 30%. It adopts imported fluorine-free foaming additive, and is fully foamed by 360 degrees, and the constant temperature setting process ensures the stability of the insulation layer and keeps heat in one step. Vacuum tube heat preservation Antarctic still use hot water The new generation of purple [Antarctic tube", which is built by Dr. Harding, the [father of the world's coating", combines variable frequency absorption technology, three-target coating technology and high-vacuum manufacturing technology to complete the heating up faster and get more heat. The heat retention is stronger and the three effects are combined, even in the Antarctic. 1. The temperature rises faster (the rare metal elements are added to the film layer, the light reflection is higher, the small sunlight can be started, the absorption ratio can be as high as 0.96, and the emission ratio can be as low as 0.04.) 2. Get more heat (based on solar spectroscopy, innovation in the traditional three-target coating technology, the purple film layer especially adds rare metals, modify the molecular structure of the film, the spectrum of the sun The long absorption range reaches 0.25-3 microns, which can absorb visible light, infrared light and local ultraviolet energy, and complete the broad spectrum absorption of sunlight, which is more heat than ordinary vacuum tubes. ) 3. The heat preservation is stronger (the film layer is specially added with rare metal, which effectively reduces the heat dissipation of the vacuum tube, the emissivity is 40% lower than that of the ordinary vacuum tube, the heat efficiency is higher, the vacuum tube is more heat-conserving, and is particularly suitable for high Cold environment. ) 4. Longer life (using high-silicon 3.3 glass, the risk of damage is not minimized; at the same time, the getter is designed for 15 years according to normal operation to ensure that the service life of the vacuum tube is longer.) The heat of the pipeline is not lost. According to the principle of thermodynamics The common exhaust design, high-efficiency pipeline anti-freeze insulation technology (optional), reduce the heat loss in the hot water pipeline transmission process, to ensure that the winter is not frozen.

2022 10/01

- Teach you how to use a spannerIntroduction: One of the hardware tools commonly used in our homes is wrenches. According to its power, it can be divided into electric wrenches and manual wrenches. At present, we use hand-held wrenches in our homes, although it is a tool that can be seen everywhere in our lives. , but its classification and use may not be understood by most people. The first and most common is the open-end wrench. The open-end wrench is also called the open-end wrench. It is divided into single head and double head. The size of the opening can be adjusted according to different nut sizes, and some will According to the existing standard size, it can be made into a set that can not be adjusted, including square, hexagonal, and dodecagonal. Among them, the dowel-shaped wrench, also called the plum wrench, is most commonly used by the public at the point. Its advantage is that Used in a smaller space, the rotation is smaller and the application is wider. It is particularly convenient to remove the hex nuts or bolts that are located in the slightly recessed area. Another common wrench is the socket wrench, which is composed of a set of different size plum blossom cylinders, in which the continuous rotation with the arcuate handle can greatly increase the work efficiency and save the physical strength. This set of wrenches also has a small space for work. This is a ratchet wrench. It has a small rotation angle, so it is suitable for tightening or unscrewing screws and nuts. There is also a type of disassembly used in electromechanics. He is an Allen wrench. This type of wrench has a long spring rod with a handle at one end and a square or hexagonal head at the other end. A replaceable sleeve fits over the square head or hex head. There is also a long pointer on the top. The scale plate is fixed on the handle and the scale value is 1 Newton (or kilograms per meter). So when the job requires a certain amount of tightening force, or when several nuts (or screws) require the same tightening force, use this wrench to help. Colleagues He was also used to dismantle large nuts, such as the common steel structure used by electricians to load and unload steel towers. There are many other common wrenches, such as a loose spanner and a live spanner, which are tools that tighten or loosen an angled screw or nut. In use, the right hand holds the handle. The more backward the hand is, the easier it is to pull it. When the small nut is pulled, because the worm wheel needs to be continuously rotated to adjust the size of the wrench, the hand should be held close to the lip, and the worm wheel is modulated with the thumb to adapt to the size of the nut. If there are too many kinds of wrenches, the examples will not be elaborated one by one. It is better to consider the scope of application when choosing the wrench. This will make it possible to choose the right type and model more appropriately. This will not only save you labor, but also improve work efficiency. . In the end, we must also remind people that people often use wrenches as hammers in daily life. This will cause great damage to the tools. Improper operation will also make the model of the wrench type. Therefore, it is recommended that the right tool be selected according to different tasks. work method.

2022 09/30

- The development of Chinese hardware tools and tools is flourishingIn the new wave of world economic integration, the global manufacturing industry has accelerated its shift to mainland China, and China will gradually develop into a world-class manufacturing base. The obvious advantages of Guangdong, especially the Pearl River Delta region, will develop into a global mold production center within 10 years. At the same time, due to the fact that China has imported molds for nearly US$1 billion per year in recent years, among which the precision, large-scale, complex, and long-life molds account for the majority, starting from the perspective of reducing imports, the proportion of such high-grade molds and hardware tools in the market will gradually increase. Increase. In the future, China's mold and CNC tool industry will also be among the best in the world. China`s daily hardware industry has entered the world`s forefront. At present, at least 70% of China's hardware industry is a private enterprise, which is the main force for the development of China's hardware industry. China has gradually become a major metal processing country and exporter in the world, and it has become one of the world's major hardware manufacturers with a vast market and consumer potential. It is not difficult to find out carefully that the development of cutting tools for Chinese hardware tools generally has a tendency. First look at the hand tool market: The demand for German hand tools has increased. In Germany, the tools for comfort and labor are the most popular. The smooth handles and beautiful appearance that help grip the tools are all important factors that appeal to their purchase. With regard to the types of tools, power tools are now becoming more and more popular. In addition, rechargeable tools have become increasingly popular. The new rechargeable tools currently on the market have multiple battery jacks that can be used in a variety of environments. U.S. hand tool market demand has stabilized. At the same time that the United States increased the scale of new homes in the housing market at the end of last year, there are still a large number of existing homes unoccupied, bringing great opportunities for housing renovation. The average vehicle type and age of motor vehicles are getting larger, which has played a certain role in promoting the sales of hand tools in the automotive aftermarket. In addition, there is strong demand for forging tools for distribution of electronic products, especially adjustable wrenches. Taiwan's hand tools industry has certain advantages in the world by virtue of its stable product quality, timely delivery, and complete product range, which can meet customer needs. Moreover, Taiwan`s hand tool sales are dominated by the off-island market. At present, there are about 5,000 local manufacturers, which are mostly located in the central area of Taiwan Island. According to relevant survey data, with regard to the category of individual hand tools, the sleeves are the bulk of exports, followed by hand tools, the third is garden tools, the wrenches are ranked fourth, and the clamps are ranked fifth. In terms of exporting countries, the United States ranked first, followed by the United Kingdom, Germany and Japan. The demand for cutting tools in the world will continue to grow. According to reports, the demand for cutting tools in the world continues to grow. Among them, European and North American countries have maintained stable growth, especially in Eastern Europe. The Asian market has seen a slight recovery. The market has great potential. The Latin American market has grown significantly, especially Mexico. In the past year, the slow growth in demand for the tool market has been mainly due to the increase in tool life and the need for users to request the entire manufacturing process instead of many machine tools and tools. And the use of multi-purpose tools has increased, replacing many simple tools that used to be single-function. Experts predict that in the future, users will place greater emphasis on the research and development of cutting tools by manufacturers, not only in the field of materials and surface coating technology, but also in the production of cutting tools and their production processes. The expert said that focusing on production practices will help toolmakers increase their market competitiveness in areas they are familiar with. Technical updates. Tool technology, cemented carbide tools gradually replace high-speed steel tools, especially circular tools. The application of coated cutters is becoming more and more common. In Europe, the market for new cutting tools for high-speed machining continues to increase. The dynamics of the manufacturers. Judging from the cooperation mode of tool manufacturers, many large companies will emerge in the high-tech market. During the tenth five-year period, the general trend of the mold market was steady upward. At present, the domestic market has a large demand for medium-to-high-grade molds, but domestic molds must meet the needs of users in terms of quality and delivery time. Moreover, the home appliances, automobiles, and plastic products industries have the greatest demand for molds. In the international market: In recent years, labor costs in industrialized countries have increased and they are moving to developing countries, especially in Southeast Asia. Its domestic production of high-precision molds, labor-intensive labor-intensive molds rely on imports to solve. Therefore, the medium and low-end mold international market has great potential. As long as the quality of domestic molds can be improved, the delivery date can be guaranteed, and the outlook for mold exports is very optimistic. In addition, the international market demand for racks and mold standard parts is also very large. At present, China only has a small amount of exports to the framework. The 11 billion yuan worth of imported tools are all modern and efficient tools. Of the 22 billion yuan worth of domestically produced knives, only about 2 billion yuan are available for modern high-efficiency knives, accounting for 10% to 15%, while foreign brands account for tool sales. One-third of China's tool consumption. This shows that while China has become the world's most promising tool market, high-end markets are occupied by multinational companies. This is a big problem. In 2011, the domestic tool market maintained rapid growth and it is expected to create a new historical high. Statistics show that only the first half of the domestic tool market achieved a growth of 25% to 30%. Although the growth rate has declined since July, it can still achieve 15% growth for the whole year. In comparison, the international tool market has maintained a stable recovery in recent years, but the conservative estimate of the average annual growth rate is only maintained at about 3% to 5%. After the domestic market has experienced rapid growth in the past year, it will gradually maintain a stable year. The average growth rate is between 10% and 15%. Therefore, the domestic tool market capacity growth rate will be more than three times faster than the international market.

2022 09/29

- Wire cutters flush the wire with high pressure water pump repairA AGIE CUT AC150F HSS low-speed wire cutting machine uses a high-pressure water pump M2 for flushing and threading. It has high vibration noise, low water pressure and instability, and the automatic threading work is not normal. The water nozzles and filters were dismantled separately, and the noise became smaller; plugging the water nozzle and replacing the filter were all invalid. Preliminary analysis has doubts about problems with the pump blades and couplings between the motor and the pump body. Because the high pressure water pump of this machine tool is replaced by domestic water pump, the effect is poor and the service life is short. Many AGIE CUT users now directly purchase imported high-pressure water pumps, but they are expensive and have a long arrival period. After analysis, we are ready to dismantle and repair ourselves. Disassembly process and solutions: 1 Remove the high-pressure water pump power cord and make a mark; 2 remove the attached line plate and filter; 3 remove the pump body and the motor connection nut, so that the motor and the water pump body separation, coupling No problem; 4 remove the pump body, first use a pipe wrench to turn the cast copper connection seat (connecting seat and the pump body for threaded connection), after unscrewing the connection seat, you can directly remove a bunch of centrifugal pump blades, in which a cast copper bracket , Up and down 11 blades, a total of 22 pieces. After cleaning with water, it was found that the shaft bores of the blades were worn out and could not be repaired, but they could also be used. The wear of the motor bushing in the cast copper bracket is the most serious, and the gap between the motor bushing and the cast copper bracket is approximately 1 mm. First, solve the problem of large lateral oscillations, and reconfigure a motor bushing (combined with the inner hole of the cast copper bracket) so that the motor bushing can be turned on the inner wall of the cast copper bracket to reduce the gap; and then solve the axial turbulence problem. , And hexagonal motor shaft with a hexagonal washer, thickness 0.6mm. Assembly process: According to the sequence of disassembly, the prepared motor shaft is set inside the cast copper bracket; 22 centrifugal blades are then installed at the two ends of the cast copper bracket through the motor shaft, and a hexagon socket is placed on every other blade pad. Washers can not be overfilled, too much will cause no gaps between the shaft; then into the pump body, tighten the cast copper connection seat, pump body assembly is completed; Finally, the pump body and the motor are assembled together, install the filter With the line plate, the high pressure water pump was successfully installed. After the repair, the effect of the high-pressure water pump reached the requirement of flushing the thread, basically no noise. Users of AGIE CUT may wish to try it when a similar fault occurs in the high pressure threading water pump.

2022 09/28

Email to this supplier